Industrial Batch Ovens

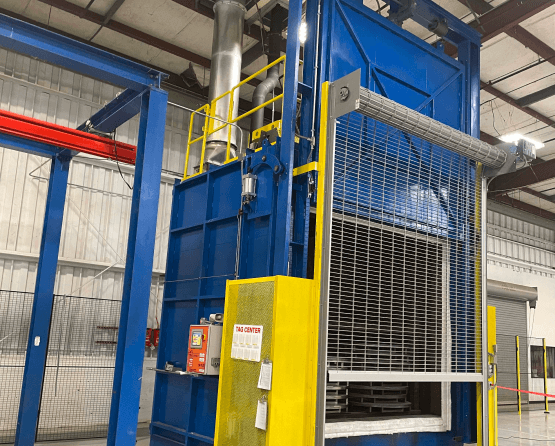

Industrial batch ovens are a type of thermal processing equipment widely used in the manufacturing and finishing processes of goods across various industries. Horizon Performance Technologies designs and builds custom industrial batch ovens for curing, drying, annealing, heat treating, and more. They are designed as five-sided chambers with thermal insulation (often featuring high temperature concrete flooring) and a product access door. The size of the batch oven is determined by the largest substrate or part that needs to be processed. They excel at handling large parts, long heating durations, and low production flow scenarios, making them ideal for applications such as a powder coating batch oven, batch curing oven, or curing station in industrial and laboratory settings.

As a leading industrial oven manufacturer, Horizon Performance Technologies specializes in designing and building batch ovens that meet the most demanding production needs. Horizon manufactures both standard configurations and fully customized batch ovens. Our team of expert engineers works closely with you to ensure your oven is designed to meet the exact specifications of your production process.

Explore the applications and industries that benefit from our batch ovens below. When you're ready to enhance your manufacturing efficiency, contact us for a custom quote.

- Operating Temperature: 1022°F

- Size: 6'-10" H x 10'-11" W x 10'-0"

- Load Capacity: 2,500 lbs/hr

- Heat Source: Gas, (1) @ 1,000,000 BTU's

- Full Load Amps: 65 Amps

- Total HP: 34.5

- Features: 8" insulation, vertical lift door, controls featuring VFD, temperature trending, and fault detection safety alarms.

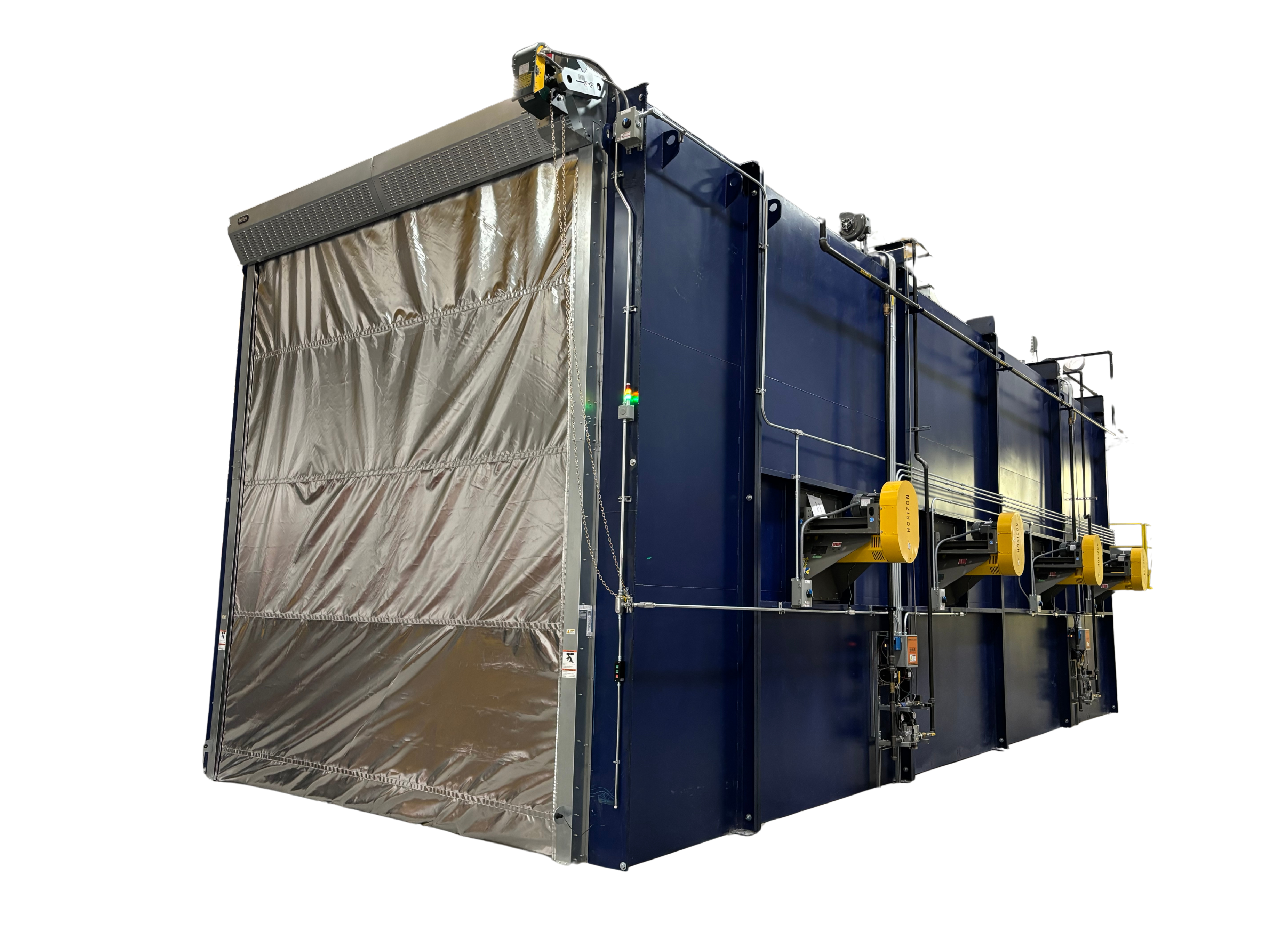

- Temperature Range: 275°F to 400°F

- Size: 13'-4" x 8'-8" x 13'-4"

- Load Capacity: 12,000 lbs/hr

- Heat Source: High-efficiency gas burners (1) @ 1,500,000 BTU's

- Full Load Amps: 35.3 Amps

- Total HP: 22.5

- Features: 6" insulation; swing door, controls featuring VFD, temperature trending, and fault detection safety alarms.

- Temperature Range: 360°F-500°F

- Size: 55' x 8'-6" x 9'

- Load Capacity: 5,000 lbs/hr

- Heat Source: High-efficiency gas burners (4) @ 500,000 BTU's/Ea

- Full Load Amps: 36.3 Amps

- Total HP: 23

- Features: 6" insulation, swing door, controls featuring VFD, temperature trending, and fault detection safety alarms.

- Temperature Range: 158°F-221°F

- Size: 26' x 7'-10" x 7'-6"

- Load Capacity: 3000 lbs/hr

- Heat Source: Electric (2) @ 36 kW/Ea.

- Full Load Amps: 119 Amps

- Total HP: 11

- Features: 6" insulation, swing door, controls featuring VFD, temperature trending, and fault detection safety alarms.

- Temperature Range: 300°F-350°F

- Size: 44' x 13' x 15'-6"

- Load Capacity: 6,500lbs/hr

- Heat Source: Gas(4) @ 1,000,000 BTU's/Ea.

- Full Load Amps: 77 Amps

- Total HP: 52.5

- Features: 6" insulation, roll up door, controls featuring VFD, temperature trending, and fault detection safety alarms.

- Temperature Range: 250°F-500°F

- Size: 50' x 14' x 14'

- Load Capacity: 2,500 lbs/hr

- Heat Source: Gas (4) @ 1,000,000 BTU's/Ea

- Full Load Amps: 75 Amps

- Total HP: 47

- Features: 6" insulation, roll up door, controls featuring VFD, temperature trending, and fault detection safety alarms.

How to Choose the Right Industrial Batch Oven

-

Part size and weight -

Determines chamber dimensions and load capacity -

Temperature requirements -

Influences heating system and insulation design -

Production volume -

Afftects oven size and automation level -

Process type -

Curing, drying, heat treating, annealing or other thermal treatments -

Energy efficiency goals -

Important for long-term operating cost control -

Facility size/layout constraints -

Available floor space and utilities

robust construction: Built for excellence-built to last

-

Durable Exterior Construction:

Horizon’s batch ovens feature a solid plate construction that is 500% thicker than conventional panel designs, preventing heat loss and contamination. The design meets NFPA guidelines and is explosion-proof. -

Seamless Design:

The welded-tight construction eliminates seams that could leak heat or allow contaminants to escape, maintaining a clean exterior and efficient heat retention within the oven. -

Superior Insulation:

The non-settling rockwool insulation, with wall thicknesses ranging from 4 to 8 inches, ensures optimal performance at temperatures up to 1200°F. -

Enhanced Interior Features:

The oven's interior is crafted from aluminized or stainless steel that is 25% thicker than typical industrial ovens. The design minimizes exterior support structure, reduces thermal bridges, and enhances heat reflection for better product processing. -

Modular Design for Future Expansion:

Ovens can be designed so that the modular construction enables easy future expansion, adapting to growing production demands without the need for a complete oven overhaul. -

Customizable Options:

Horizon offers various accessories, including roof safety railings, access ladders, PLC controls, roll-up doors (under 500°F), thermal oxidizers, and heat recovery systems, allowing for tailored solutions to specific industrial needs.

Industrial Batch Process Ovens Provide a Variety of Heating Solutions

- Adhesive/Gel Curing

- Composite Curing

- Quenching

- Aging

- Drying Water/Other

- Sintering

- Annealing

- Hardening

- Stress Relieving

- Burn Off

- Powder Coating

- Tempering

- Bonding

- Pre-heating

- Thermoforming

Horizon designs each oven around the unique requirements of your application. Learn more about the range of thermal processes we support.

horizon Batch ovens serve a Wide Range of industries

-

Aerospace:

Composite curing and high-temperature processes -

Automotive:

Curing automotive paints and heat treating metal parts -

Aluminum & Metal Fabrication:

Annealing, bonding, and finishing -

Battery & Energy:

Thermal processing of battery components -

Carbon Fiber & 3D Printing:

Post-processing and curing -

Electronics:

Drying and curing components -

Foundry:

Sand core drying and other high-temperature processes -

Healthcare:

Sterilizing and curing medical devices

Learn more about the industries we support and the role Horizon Cyclone Ovens play in perfecting thermal processing.

Efficiency through Innovation: cyclone Technology saves money & resources

Horizon’s Cyclone Technology revolutionizes the efficiency of the industrial batch oven. By optimizing airflow and temperature distribution, it significantly reduces processing times and energy consumption.Cyclone Technology delivers up to 80% energy savings, significantly lowering operating costs while supporting sustainability goals by reducing your facility’s carbon footprint.

Key Benefits Include:

-

High-Efficiency Airflow:

High-volume, low-pressure airflow to optimize heat transfer, leading to shorter process times. -

Reduced Motor Horsepower:

Cyclone Ovens require 75-80% less motor horsepower for recirculation fans compared to conventional ovens, resulting in substantial electricity savings over the equipment's lifetime. -

Energy Conservation and Savings:

Increased insulation thickness minimizes gas consumption, lowers BTUs needed for heating, and reduces wall loss (the heat energy that escapes through the walls of the oven, rather than being retained within the oven chamber), leading to significantly lower operating costs. -

Smart Control Systems:

Equipped with variable frequency drives and HMI systems, Horizon's batch ovens offer precise control over the heating process, ensuring consistent temperature control and adaptability to changing production loads. -

Reversible Air Recirculation:

Automated through PLC controls, this feature allows the oven to reverse airflow during cycles, ensuring uniform heat distribution and enhancing process capabilities for sensitive materials.

superior Performance: The Cyclone Technology difference

-

Temperature Uniformity:

Cyclone Technology provides the industry’s most superior temperature uniformity allowing for a more consistent product temperature. This ensures the highest possible product quality, and is especially critical in industries like aerospace, automotive, and composites manufacturing. -

Faster Heat-Up Times:

Higher velocity airflow at the product surface enables quicker heat transfer, resulting in shorter heat-up times. In some cases, this may allow for the use of smaller batch ovens (depends on the specific requirements of each application). -

Motor Size Versus Conventional Ovens:

Unlike conventional ovens that rely on high-velocity nozzles which lose efficiency quickly, Cyclone Technology maintains consistent airflow and temperature with motors that are 1/4 to 1/5 the size, delivering better performance with less energy. -

Versatility Across Applications:

Our custom batch ovens produce high quality results in a variety of processes and industries. Whatever your challenge, Horizon can custom engineer and build the exact oven you need!

FREQUENTLY ASKED QUESTIONS

What's the difference between a batch oven and a conveyor oven?

Batch ovens process materials in groups/batches, ideal for large parts or varied products. Conveyor ovens provide continuous processing for high-volume, consistent parts.

How long does batch oven installation take?

Depending on oven size and configuration, anywhere from 2 days up to 2 weeks or more.

What maintenance is required for industrial batch ovens?

Industrial batch ovens require regular maintenance to ensure peak performance and extend their lifespan. Key components like burners, gas trains, door seals, fans, and control panels should be inspected and cleaned on a set schedule. Horizon ovens include a detailed maintenance plan outlining specific tasks and intervals to keep your equipment running reliably and efficiently.

Can batch ovens handle different part sizes simultaneously?

Yes, with proper rack design and airflow management. Temperature uniformity may vary with mixed loads.

How do I know if the Cyclone Oven™ is right for my process?

Horizon engineers are uniquely equipped to ensure your product and process are perfectly matched to our Cyclone ovens. We tailor oven designs to deliver optimal results and verify those results in our in-house lab.

Ready to Optimize Your Manufacturing Process?

At Horizon, we're not just building industrial batch ovens, we're creating solutions that drive your business forward in a cost-saving, eco-friendly way. Contact us today to discuss your needs and discover how a custom Horizon Oven with Cyclone Technology can revolutionize your manufacturing process!