Why “Meets Temperature” Isn’t a Performance Spec—The Critical Metrics of Thermal Processing

Most industrial ovens can reach a setpoint.

Far fewer deliver consistent thermal conditions to real parts, under real production loads, day after day.

This disconnect between displayed temperature and actual part exposure is one of the most common causes of quality variation, extended cycle times, and excessive energy use in thermal processing. It’s also where many oven specifications fall short.

If you want performance that holds up on the floor, not just on a datasheet, three fundamentals must be specified and verified:

- Temperature Uniformity

- Airflow

- Heat Transfer to the Part

Treating any one of these in isolation almost guarantees surprises after installation.

Temperature Uniformity: Avoiding Hot and Cold Spots is Critical

Temperature uniformity is typically defined as a ±°F value around setpoint.

What uniformity actually needs to mean

A usable uniformity specification answers these 4 questions:

- Where is it measured? It must be defined across the entire usable work chamber.

- When in the process is it measured? In addition to steady state, many processes are also affected by ramp and transition behavior.

- Under what load conditions? A true predictor of success is loaded uniformity using representative parts, fixtures, and space. This better correlates to real world performance.

- How quickly does it recover? A meaningful spec includes recovery time back to setpoint and back to uniformity.

Air patterns change once parts are introduced, creating hot and cold pockets. Masking the issue by increasing soak times or setpoints can reduce throughput and increase energy expenditure. Uniformity that only exists in an empty oven is not uniformity you can run production on.

Airflow: the Delivery Mechanism for Heat

Airflow is the least understood variable in convective industrial ovens. Specifications often refer to fan horsepower or total CFM but neither describes how heat is actually delivered to the load. Airflow performance is about distribution, stability and load tolerance.

Airflow criteria that matter are:

- Air velocity at the part surface or defined measurement planes

- Acceptable velocity variation across the work envelope

- Defined flow pattern (such as Cyclone’s patented air movement)

- Performance under load ensuring airflow doesn’t collapse when parts restrict movement.

Uneven airflow can create uneven heat transfer even when chamber temperature sensors appear stable. Airflow performance should be discussed by each oven designer/manufacturer and judged by measuring performance under load for best predictive results.

Heat Transfer: the Metric that Ties it All Together

Air temperature does not cure coatings, dry parts, or stress relieve metal. Heat transfer to the part does.

Two ovens can meet identical temperature specifications and still produce very different part outcomes. The difference lies in how efficiently and evenly heat moves from the oven environment into the product.

Why chamber temperature is not the process

Parts respond to:

- Convective heat transfer driven by airflow velocity and direction

- Conductive paths through fixtures and racks

- Radiant heat from surrounding surfaces

If airflow is uneven or unstable, part temperatures will lag or overshoot. This leads to edge overheating, cold cores, inconsistent cure, and extended cycles added as insurance.

Practical ways to specify heat transfer

Heat transfer can be specified in clear, verifiable terms:

- Part thermocouple response

- Time to reach target temperature

- Maximum part-to-part temperature variation at defined times

- Limits on overshoot or lag

- Heat-up rate under load

- Degrees per minute for a defined thermal mass and configuration

- Soak stability at the part

- Temperature consistency during dwell

These metrics directly connect oven performance to throughput, energy use, and quality.

Why Airflow Architecture Determines Real-World Performance

Uniformity, airflow, and heat transfer are inseparable—airflow is the common link.

Many ovens perform well empty but become unpredictable once parts obstruct the flow. Localized jets, poor return paths, or short-circuiting airflow create conditions that look acceptable on paper but vary widely at the part.

Airflow architecture rather than raw airflow volume addresses this issue. For example, Cyclone Technology™ developed by Horizon Performance Technologies, uses a controlled supply and return approach designed to maintain stable, full-chamber airflow under load. The objective is not higher velocity, but more consistent heat delivery and recovery when production conditions change.

The broader takeaway is universal: airflow design, not fan size determines whether performance specs survive real production. Horizon Cyclone Technology™ does not rely on oversized fans, excess static pressure or brute-force airflow volume. Instead, our trademarked technology uses meaningful air velocity at the part surface because convective heat transfer requires it.

Final Thought

If your specification only describes temperature, you are leaving performance to chance.

When uniformity is defined in context, airflow is treated as a critical variable , and heat transfer is tied directly to part response, oven performance becomes predictable and repeatable.

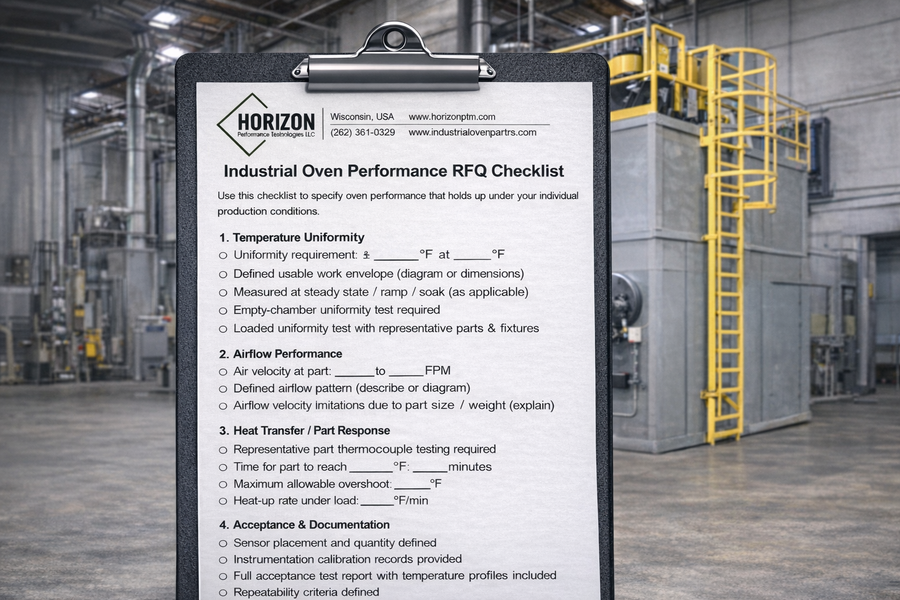

That’s when the numbers on the page start showing up on the floor. Get started with this checklist. CHECKLIST