A cabinet washer, also commonly referred to as a batch washer or an industrial parts washer cabinet or industrial cabinet washer, is used to pretreat metal parts prior to powder or liquid coating. The parts are brought into the washer in “batches” rather than moving through on a continuous conveyor. The parts are typically on carts or hung on a manual or indexing conveyor.

Horizon offers customers customizable cabinet washers that suit a wide variety of cleaning needs, from simple degreasing and particulate removal to multi-stage washing, rinsing, and surface preparation. Each system is engineered around the part geometry, contamination type, throughput requirements, and downstream process—ensuring consistent cleanliness, improved coating performance, and repeatable results across a wide range of manufacturing applications.

Custom Made Cabinet Washers for Specific Needs

Horizon designs and builds custom cabinet washers to serve a wide range of industries and virtually unlimited part sizes. From automotive components and generator fuel tanks to classroom furniture, bike racks, trash containers, snow removal equipment, trailer parts, and heat exchangers, our washers are engineered to handle parts with vastly different sizes, shapes, materials, and contamination profiles. This flexibility allows manufacturers to achieve consistent, repeatable cleaning results.

Because no two parts require the same cleaning approach, Horizon designs each cabinet washer around the specific process requirements of the application. By building the washer to match the process—not the other way around— Horizon delivers cleaning systems that improve performance, reduce rework, minimize waste, and integrate seamlessly into existing manufacturing operations.

Horizon Performance Technologies LLC (Horizon) utilizes its trademarked Torrent Technology™ in its cabinet pretreatment washers, supplying many advantages over conventional washers:

Advantages of Horizon Cabinet Washers

-

Footprint Efficiency & Cost Benefits

A cabinet washer can have one product door for parts to enter and exit, or entry and exit doors on opposite sides. Because parts are cleaned in place, a cabinet or batch washer requires a smaller footprint and lower equipment cost than a comparable continuous conveyor washer.

-

Safety and Personnel Exposure Reduction

Compared to manual cleaning in a wash booth, a cabinet washer occupies less floor space, reduces personnel exposure to chemicals, and requires less labor to operate.

-

Benefits for Coating Adhesion and Longevity

Pretreatment washers clean and prepare metal parts prior to coating. This multi-stage process cleans the surface and applies a conversion coating before powder or liquid coating, improving adhesion and increasing coating durability and service life.

-

Multi-Stage Processing in a Single Compact Unit

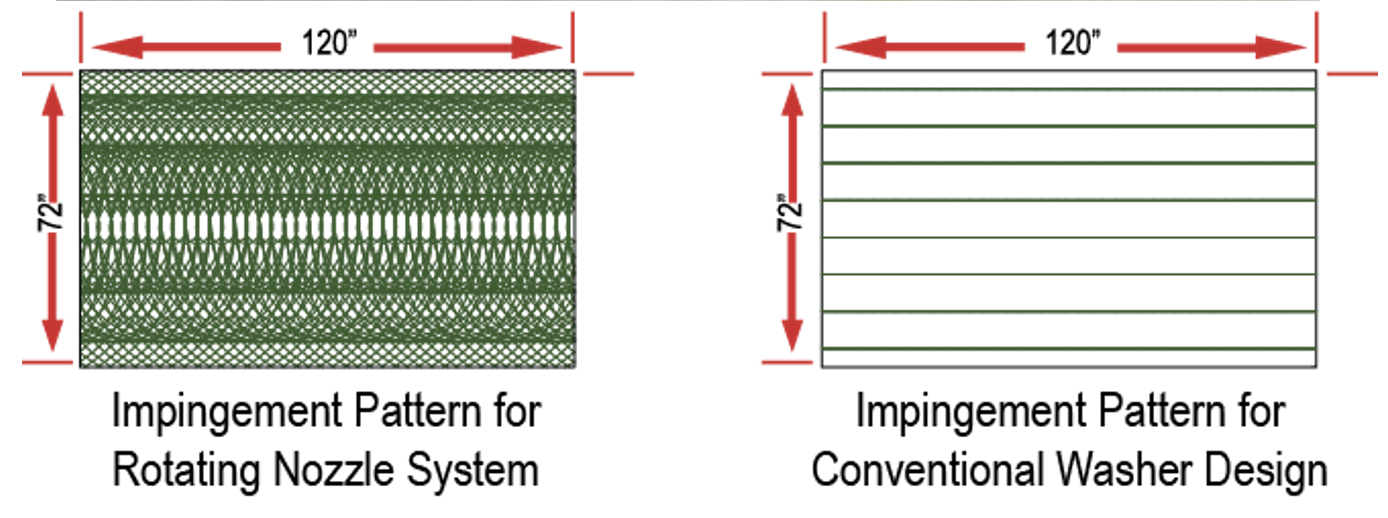

Because the spray bars rotate, the Torrent design enables a multi-stage pretreatment process within a single cabinet. The resulting swirling spray pattern provides excellent coverage, even though parts remain stationary inside the washer.

-

Dramatically Improved Cleaning Performance

Rotating risers significantly increase spray velocity, improving wash and rinse effectiveness. Higher impingement enhances chemical coverage on complex part geometries. Typical average nozzle rotational or sweep velocity is approximately 70 ft/min.

-

Reduced Water Flow & Operating Costs

Reduced wash and rinse flow results from replacing multiple riser columns found in conventional washer designs. Torrent Washers™ typically use about one-fifth the number of spray nozzles of standard riser-type washers.

- Reduced evaporation losses, lowering heating energy, water makeup, and chemical usage

- Limited or eliminated exhaust requirements, reducing plant ventilation and air makeup energy

- Lower solution flow, enabling smaller pumps and reduced electrical consumption

- Reduced system volume, allowing smaller tanks and lower disposal costs

- Fewer nozzles, translating to reduced maintenance and improved uptime

How Cabinet Washers Work: Rotating Risers for Superior Cleaning

Cabinet, or batch, pretreatment washers are designed around a series of solution or water tanks that correspond to each stage of a multi-stage process. During operation, liquid from each tank is pumped through spray mozzles and applied to the parts contained within the washer canopy. In a batch washer, the parts remain stationary while each process stage, such as cleaning, rinsing, or pretreatment, is applied sequentially, ensuring controlled exposure at every step.

Pretreatment washing itself is a critical step for manufacturers that produce painted or coated metal parts. This applies whether pretreatment is performed in-house as part of a powder or paint line, or outsourced to a finishing supplier. Cabinet washers equipped with Horizon Torrent Technology™ are used not only for traditional multi-stage pretreatment systems, but also for single-stage pretreatment and coating processes. One example is organic phosphating applications, such as plaforization, where consistent coverage and controlled chemistry are essential.

Horizon’s patented Torrent Technology™ represents a significant evolution in cabinet washer design. Instead of relying on multiple stationary riser columns packed with nozzles, Torrent Washers™ use rotating riser bars with attached spray nozzles. As these risers rotate, the nozzles move in a circular pattern, creating a swirling spray that delivers excellent coverage with fewer nozzles and lower overall water flow. Reduced flow translates directly into lower pump horsepower requirements, reduced electrical energy consumption, and decreased chemical usage. The rotational motion also increases spray impingement, improving cleaning performance, especially in hard-to-reach areas and recessed features.

Additional performance benefits come from precise process control. The rotating spray pattern excels at cleaning leading and trailing edges of parts, as well as pockets and complex geometries that are often missed by stationary systems. Between each stage in a multi-stage process, common piping is blown out with compressed air to minimize chemical carryover from one stage to the next. Pumps and rotating motors are controlled by variable frequency drives (VFDs), allowing operators to fine-tune flow rate, pressure, and rotational speed to match specific part geometries and process requirements.

- Stainless Steel Construction – roof, walls, drain boards and production doors.

- Stainless Steel Wetted pumps.

- Stainless Steel Process piping.

- Stainless Steel Nozzles.

- Stainless Steel Plank grating for internal walkway.

- Stainless Steel, welded, leak tested tanks. Tank bottoms are pitched to a drain connection.

- Stainless Steel Tank covers with handles and latches.

- Vertical Pumps – seal less and VFD controlled.

- The rotating risers have adjustable speed drive mechanisms, which allows them to not be dependent on water pressure.

- The rotating unions are ceramic coated stainless steel, and oversized gearboxes are used for years of trouble-free service.

- Header pressure is continuously monitored.

- Access doors.

- Screens in each tank located in the charge box areas, prior to the pumps.

- Optional electronic liquid level sensing and control.

- Optional internal lights.

- PLC with PanelView HMI – allows adjustment of nozzle arm rotational speed, nozzle flow, and cycle times. Also, specific recipes can be developed and programmed, such as recipes for light, medium, and heavy parts.

- Maxon, Eclipse, or Midco natural gas or propane fired burners.

- Incoloy sheathed, electric, immersion heaters. Flanged connections for ease of maintenance.

- Compressed air tank to blow out common process piping between stages, decreasing “carryover.”

Batch & Cabinet Washer Construction and Accessories

Batch & Cabinet Washer Accessories

Filtering – stainless steel bag filter housings equipped with isolation valves. Pressure monitoring is available which will provide for filter cleanliness and pressure feedback. This can notify the operator to maintain the filter and/or shut down the system if the filter is not changed and the system falls out of spec.

Magnetic Filter - Magnetic Separator with Drain Board to remove magnetic fines from the process water. The return water passes across the magnetic filter where fines are collected. This accessory is removable from the washer to allow for easy removal of the fines.

Internal LED Lighting – LED lights mounted externally to the chamber, over a tempered glass window. The operator can turn the lights on/off via the operator interface terminal.

Oil Coalescer – The unit is located next to the washer and works in a side stream fashion, drawing a water/oil mixture off the top using a floating head and diaphragm pump. The fluid is routed through a filter bag and then through multi-matrix plastic coalescing media. The removed oil is routed to a container for disposal by the customer. The remainder of the fluid is returned to the washer. Coordination with the chemical vendor is recommended.

Blow-Off System – A high efficiency blower is used with air knives or air cannons to remove excess moisture from the products as they exit the washer. The adjustable air knives/cannons are located inside the canopy at the exit of the washer. The air knives/cannons can be positioned to address areas where water tends to collect on the product. The system is much more efficient than using compressed air for blow-off.

Mist Eliminator – If the Torrent Washer™/coater is being used for a coating process, such as an organic phosphating process like Plaforization, conserving the coating liquid is economically desirable. The mist eliminator is a low pressure drop, vane type, with stainless steel construction, for vertical gas flow. It traps and drains a significant portion of the aerosolized coating liquid that would otherwise be carried out with the exhaust.

- Carbon filter, FRP tank, brass control valve, for chlorine removal from city water supply.

- Duplex water softener, FRP tanks, water meter, salt tank with salt grid and safety shutoff float, for removal of mineral hardness from the water supply.

- Reverse Osmosis machine to reduce the incoming water total dissolved solids by 97-98%. Includes: low energy membranes, permeate and concentrate flow meters, concentrate and recycle flow control valves, high pressure pump, 316 SS membrane housings, automatic inlet shutoff valve, low inlet pressure switch, inlet and outlet sample valves, pre filter – post filter – primary and final pressure gauges, 1.0 micron pre filter, powder coated steel frame, and NEMA 1 control box.

- Transfer pump to continuously circulate the stored RO water and pressurize the water going out to distribution.

- Poly RO water storage tank. Includes flow controller with internal piping to continuously circulate and mix the RO water.

- Conductivity meter and sensor for remote monitoring of the stored water quality.

- UV light in 316 SS housing installed in the RO storage tank recirculation line piping, for bacteria kill.

Water Treatment System - Complete Water Treatment Systems are available including:

Frequently Asked Questions

What is an industrial cabinet or batch washer and how does it work?

Answer: An industrial cabinet or batch washer is a contained cleaning system where the parts being serviced remain in a stationary position while cleaning stages are performed sequentially. Parts are loaded into the cabinet and water, or chemical solutions, are sprayed under controlled pressure and temperature.

Horizon batch washers can execute many stages within the same cabinet. Wash, rinse, seal, dry, or coating can all be performed in one place without a need to move the parts. Because the parts do not move, this type of washer is ideal for:

- Lower to medium production volumes

- High cleanliness requirements

- Mixed part sizes and geometries

How do you reduce chemical and water consumption in batch washers?

Answer: System design — not merely operating practice — is the best solution to reducing the consumption and waste of water, chemicals, and energy. Horizon Washers with patented technology utilize fewer nozzles to perform a more comprehensive clean. This design advantage necessitates less water, fewer pumps, reduced energy usage, and subsequently less waste.

What determines cleaning performance in a cabinet washer?

Answer: Cleaning performance is contingent on several factors. Some outcomes are a direct result of the washer design; others are a byproduct of chemistry or the process itself.

- Mechanical energy — spray pressure, nozzle design, and coverage. Torrent’s rotating arms are unmatched in this category.

- Chemistry — detergent type, concentration, and compatibility. Work with a trusted supplier.

- Temperature — solution temperature and heat retention. Optimize your process and rely on your PLC.

- Time — dwell time for each stage. Ensure dwell time for each stage is sufficient for maximum process results.

- Spray pattern consistency — uniform spray impingement is required, not just higher spray pressure. Learn more about Torrent Technology and how it outperforms others in spray impingement.

- Filtration effectiveness — screens, strainers, bag filters, magnetic filtration, oil skimmers and more must be optimized for your process. Horizon can build your washer to maximize filtration efficiency.

What industries use cabinet washers?

Answer: Any industry where oils, coolants, soils, or coatings are applied to metal. This includes but is not limited to:

- Automotive

- Aerospace

- Appliance manufacturing

- Medical components

- Fabricated metal

- Powder coating and paint pretreatment

Which is better, batch washer or conveyor washer?

Answer: Neither is “better”. They both address different production needs.

Cabinet or batch washers are better for:

- Lower volumes

- High mix

- Variable part sizes

- Tight cleanliness or coating specifications

Continuous or belt washers are best for:

- High volumes

- Inline processing with ovens and coaters

- Uniform part sizes

Brands