- Switches and Relays

- Breakers

- Terminal blocks

- Contactors

- Transformers

- Power Supply

- Motor drives

- Wire & Wireway

Industrial Control Panels

An industrial control panel is used for control of mechanical equipment and machinery. They are typically made up of two or more electrical power and control components. Typical components in an industrial control panel can include, but are not limited to:

Control panels can be put into service for indoor or outdoor use, depending on the NEMA rating such as 3, 4, or 12. These panels can also be modified for specific areas for hazardous locations. The European alternative to NEMA ratings are IP ratings. See below chart for a summary of some NEMA and IP rating enclosures.

| Classification | Used For | IP Rating |

|---|---|---|

| NEMA 1 | To protect from objects and personnel, but no protection from dust, oil, water or dirt. | IP23 |

| NEMA 2 | Indoor use. Limited protection from water and dirt. | IP30 |

| NEMA 3 | Outdoor use. Protection against solid elements, but limited protection from water. | IP64 |

| NEMA 3R | Typically, outdoor use for junction boxes. Some protection against elements. | IP32 |

| NEMA 4 | Used where a washdown occurs. Protections from pressurized stream of water. Door is clamped with gasket. | IP66 |

| NEMA 4X | Used for protection against harsh environments. | IP66 |

| NEMA 6 | Indoor or outdoor use. Protection against entry of water when submersed at limited depth. | IP67 |

| NEMA 12 | Indoor use. Protection against drips, falling dirt, and non-corrosive liquids | IP55 |

| NEMA 13 | Indoor use. Protection against dust, spraying water and non-corrosive liquids | IP65 |

Efficiency and Innovation for Industrial Control Panels

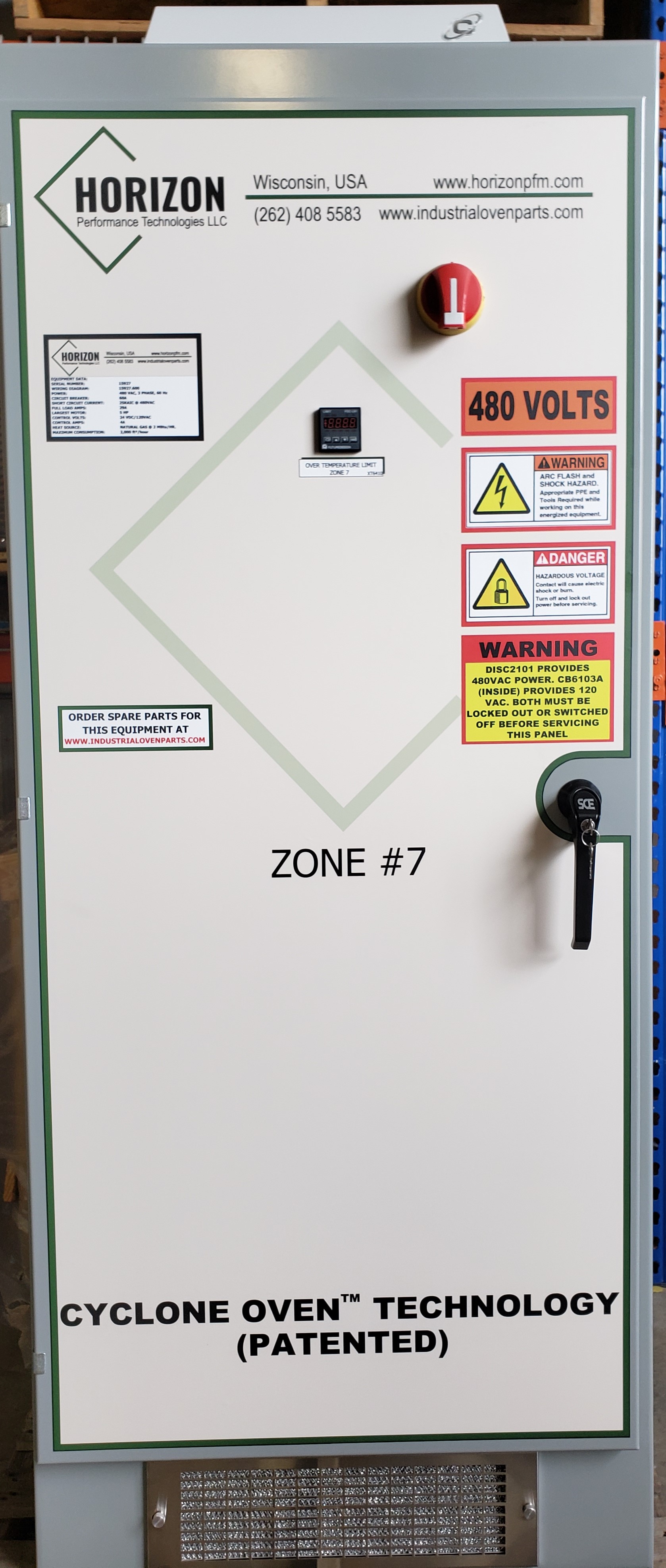

Horizon Performance Technologies LLC (Horizon) designs and builds all of our control panels. These control panels, along with the combustion gas trains, allow customers to operate their equipment safely and conveniently from one location. The control panel can be stand-alone or mounted directly to the equipment.

Components in our control panels include: VFD’s, SCR’s, PLC’s, HMI’s, circuit breakers, push-buttons, switches, relays, terminals and more. The PLC operates the equipment and monitors critical safety components that provide indication of heater or fan related issues, which can be accessed, and rectified via ethernet.

An HMI is used to interface the control panel with the human operator. Typically, our control panels will have a PanelView or multiple keyboards for the HMI. The PanelView HMI is typically a touch screen about 7 to 10 inches wide, and is interfaced with the PLC that will allow for control and management of the entire system.

Safety is always a concern when designing industrial control panels, which is why Horizon offers several additional safety components such as motor disconnects and finger-safe parts.

Horizon uses top of the line technology to best suit your system requirements. In order to do so, we have strong relationships with leading manufacturers of control components. Manufacturers we use include: Allen Bradley, Eaton, Hoffman, SCE, Phoenix Contact, Watlow, and more.

- Complete prewired electrical components.

- NEMA 12, 4, or 4X enclosures.

- Option stainless-steel enclosures.

- Circuit breakers and IEC motor protectors with contactors.

- Variable frequency drives to control fans, conveyor, pumps, etc.

- Option PLC and HMI touch screen operation.

- Digital temperature controllers interfaced to the PLC.

- Switches, pilot lights, timers, relays, terminals and more.

- Stack lights with alarms buzzer. Silencing circuit typically located on the panel.

- Option motor disconnects switches to lock out motors

As a trusted control panel manufacturer, Horizon Performance Technologies provides reliable, expertly engineered solutions for a wide range of industrial applications. Each panel is meticulously built to ensure performance, safety, and long-term reliability in demanding environments. Whether you're looking for a standalone unit or a system integrated directly into your equipment, Horizon delivers quality from design through production.

Every industrial control panel for industrial machinery is tailored to meet your specific process needs, including heating, conveying, washing, or curing. As your systems evolve, our flexible control solutions scale with your operation. If you're searching for a control panel industrial solution that balances rugged construction with modern automation, Horizon can custom-build to match your exact requirements.

Industrial Control Panel Construction and Features

Brands