INDUSTRIAL DRUM WASHERS

Rotary Drum Washers For High-Volume Parts Cleaning

Industrial drum washers, also known as rotary drum parts washers, are advanced automated cleaning systems that revolutionize how manufacturers clean large volumes of small to medium-sized parts.

Drum Washers are well suited to very economically clean a large volume of small parts such as stamped components or fasteners. These high-efficiency systems efficiently process 10,000 to 45,000+ lbs of small to medium-sized parts per hour. In addition to cleaning, they can also be used for a metal surface treatment process such as pickling or passivating.

Beyond standard processes, drum washers excel at phosphating, rust prevention treatments, and degreasing operations. They are used in fabrication processes across a wide range of industries, like automotive manufacturing, metal finishing and fabrication, and aerospace and defense.

Key Benefits of Industrial Drum Washers

- Cost-effective cleaning for high-volume production – Typical ROI achieved within 6–12 months

- Gentle tumbling action prevents part damage – Ideal for delicate precision components

- Suitable for continuous or batch operations – Maximum operational flexibility

- Multi-stage capabilities (wash, rinse, dry) – Complete cleaning solution

- Reduced water consumption up to 60% with integrated RO systems

Custom-Engineered Drum Washers for Your Application

We custom design rotary drum washers for optimum performance and efficiency. Critical design factors we evaluate include: product throughput required, product type and shape, required processes, number and types of stages, spray or immersion, drum diameter, drum rotation speed, internal helix height/length/pitch, product cooling, product drying to produce the optimum design for maximum efficiency.

Industrial drum washer sizes range from 12 to 72 inches and feature a stainless-steel drum and internal helix, canopy, tanks, and process piping. the PLC with HMI enables control of drum rotation speed, flow rate, nozzle pressure for each stage, and specific recipes for various part types.

Our experience and attention to detail and quality throughout all phases of the project, i.e., design, fabrication, installation, start-up, and post-installation follow-up, ensure the highest quality equipment and results.

How Industrial Drum Washers Work

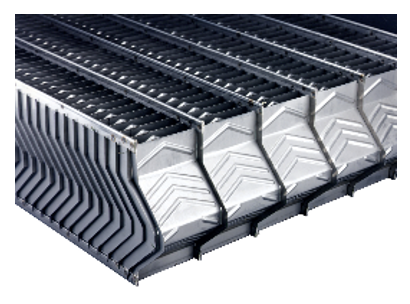

Rotary Drum Parts Washers have a rotating, perforated drum with an internal helix. The parts to be cleaned/processed are placed in one end of the drum, are tumbled and moved through the drum by means of the internal helix and the rotation of the drum, and the cleaned/processed parts exit the opposite side of the drum.

Spray nozzles and piping are in the center of the drum, and spray water/solution onto the parts as they pass through the drum. Rotary parts washers can be single or multi-stage, and can also include drying or cooling of the parts.

Rotary drum parts washers operate in either batch or continuous configurations, with parts tumbling through a rotating drum as they are sprayed or immersed at each stage of the process. The drum is driven by an electric motor using a chain or direct drive system, with rotation speed controlled by a VFD. Each stage includes its own stainless-steel tank and pump, allowing for ambient or heated solutions delivered by submerged tubes, gas burners, or electric elements, with optional ambient or heated air drying and ambient or chilled air cooling available.

Industrial Drum Washer Construction and Features

- Stainless steel construction for the drum, internal helix, walls, roof, drain boards, and tanks

- Stainless steel piping

- Stainless steel, VFD-controlled pumps

- Stainless steel or clip-on polypropylene nozzles

- Stainless steel, welded, leak-tested tanks

- Stainless steel handles and latches on tank covers

- Access doors for maintenance and inspection

- Screens in each tank located in the charge box areas prior to the pumps

- Optional electronic liquid level sensing and control

- PLC with PanelView HMI

- Maxon, Eclipse, or Midco natural gas or propane-fired burners

- Incoloy-sheathed electric immersion heaters

Advanced Options & Industrial Drum Washer Accessories

Filtering – Unfiltered liquid enters the filter above the bag or basket and passes down through them where solids are contained (<5 µm particle removal). The covers of the filter are easily removable without tools.

Magnetic Filter – Magnetic fines from the process water will be eliminated with the use of a magnetic filter/separator. Fines are collected where the water passes across the filter. The fines are easily removable because the filter is removable.

Oil Coalescer – Before the water returns to the tank, the solution will be filtered and then will pass through oil separation (99% tramp-oil separation). The tank is constructed of 304 stainless steel and is welded water tight.

Blow-Off / Drying System – Air knives or air cannons are used to remove excess moisture from products as they exit the washer (<0.1 g residual water/part). The air knives or cannons can be positioned to target areas where water tends to collect. Compared to usingcompressed air, the blow-off system is more efficient. Heated air blow-off is available.

Mist Eliminator – If the rotary drum washer is being used for metal surface treatment processes such as pickling, preventing or reducing aerosolized pickling solution from being exhausted is desirable. The mist eliminator is a low-pressure-drop, vane-type with stainless steel construction, for vertical gas flow, It traps and drains a significant portion of the aerosolized coating liquid.

RO Water Treatment System – Reverse osmosis (RO) is used in our water treatment system. Using RO can reduce water consumption by 60%, decrease chemical usage, and improve overall finish quality.

Proven Performance Across Industries

Rotary drum parts washers are ideal for a wide range of applications, including:

- Automotive – engine and transmission parts

- Aerospace – precision hardware and landing-gear components

- Fastener OEMs – screws, bolts, and rivets

- Electronics – shielding and stamped contacts

- Medical – implants and surgical tools

Brands

Ready to optimize your manufacturing process?

At Horizon, we're creating solutions that drive your business forward in a cost-saving and eco-friendly way.

Contact us today to discuss your needs or request a quote for a custom industrial drum washer.