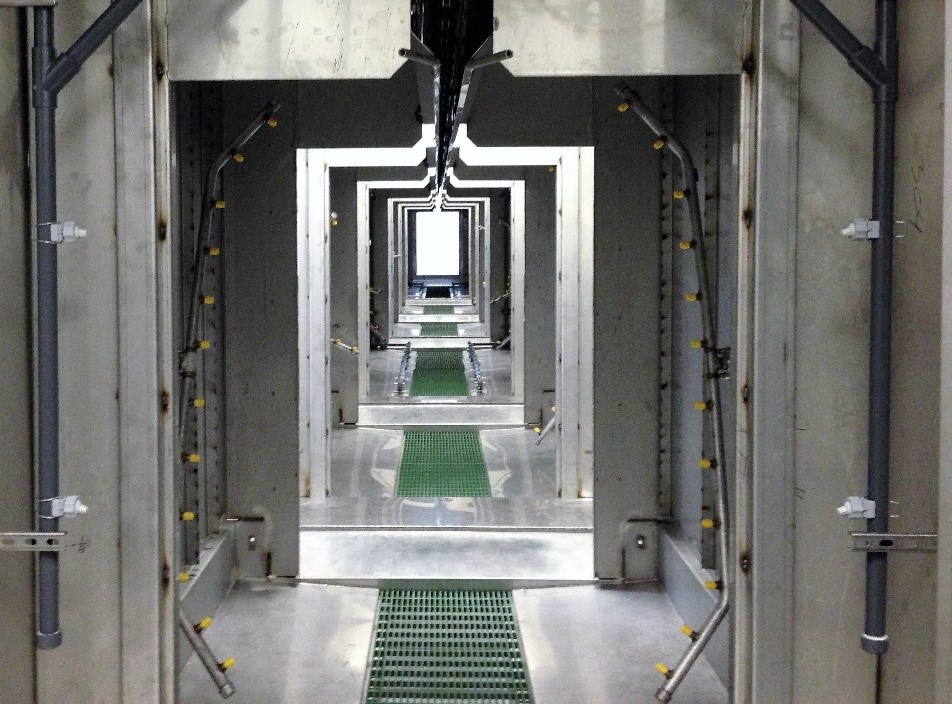

Industrial mono-rail parts washers, a specialized type of conveyor washers, are used to pretreat metal parts prior to powder or liquid coating. The parts are hung on a continuous motorized conveyor, enclosed track or I-beam, which moves the parts through the washer. A continuous monorail parts washer has a higher production rate with less labor than a cabinet and batch washer.

Main Factors to Consider in Washer Design

- Part sizes, orientation, and materials of construction

- Conveyor line speed

- Process specification (typically provided by the customer’s chemical supplier.)

- Washer’s materials of construction

- Spray system design

- Heating system requirements

- Washer housing cross section and drain lengths

- Exhaust Fan requirements

- Solution tank size requirements and burner tube accommodation (if applicable)

- Serviceability and maintenance

Torrent Washers™ have riser bars with attached nozzles that move in a circular pattern as the riser bars rotate.

Fewer nozzles are required due to the circular motion, which results in less water flow. Less water flow means less pump horsepower, less electrical energy costs, and less chemical usage.

A swirling spray patterns results due to the rotating action which provides excellent coverage. The rotational velocity adds to the impingement of the water spray on the parts. VFD’s control the pumps and rotating motors.

The innovative, patented, Torrent Washer™ design, exclusively produced by Horizon, supersedes the older conventional design of washers, which uses multiple riser columns of many stationary nozzles.

The innovative, patented, Torrent Washer™ design, exclusively produced by Horizon, supersedes the older conventional design of washers, which uses multiple riser columns of many stationary nozzles.

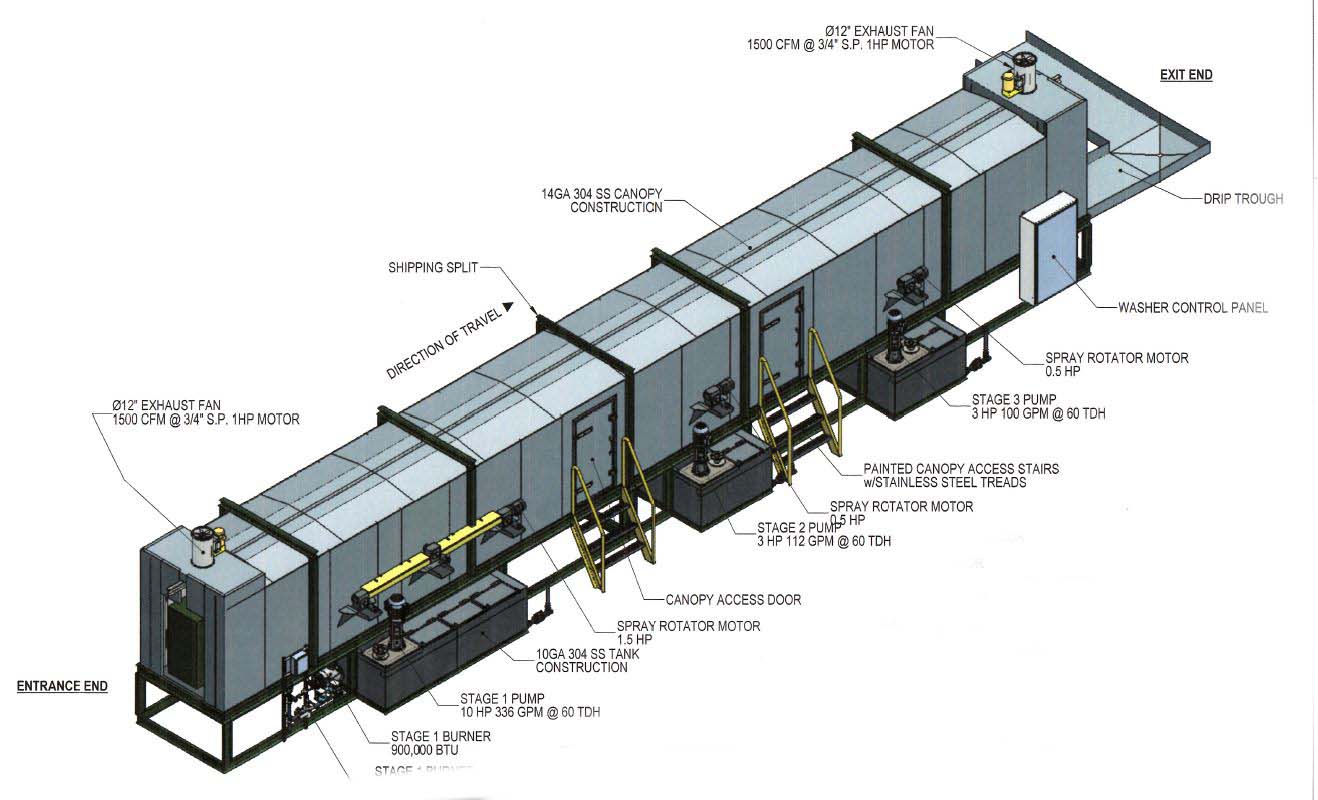

Multi-Stage Pretreatment Process

Multi-stage pretreatment washers are used by virtually every manufacturer that uses painted metal parts in their products; whether directly in their own in-house powder/paint line, or indirectly through out-sourcing.

The pretreatment process is typically a multi-stage process that cleans and applies a conversion coating to the parts prior to powder or liquid coating. The process improves the adhesion of the powder or liquid coating to the part surface and increases its effective longevity and corrosion protection.

In general, conversion coatings are iron phosphate, zinc phosphate, or the more environmentally friendly and versatile zirconium.

The pretreatment washers have solution/water tanks for each stage of the multi-stage process. The liquid in these tanks is pumped through spray nozzles onto the parts inside the canopy of the washer. In continuous monorail washers, by means of the conveyor, the parts move through each of the washer’s stages, e.g., cleaner, rinse, rinse, conversion coating, rinse.

Electrical Energy Savings

Below is a comparison between a proposed Torrent Washer™ and an existing, conventional design five-stage washer with a line speed of 12 ft./min.

Torrent Technology™

5-Stage Continuous Washer

| Stage | Flow Rate | Pump HP | Rotator HP |

|---|---|---|---|

| Stage 1 | 294 | 10 | 1.5 |

| Stage 2 | 98 | 5 | 0.5 |

| Stage 3 | 98 | 5 | 0.5 |

| Stage 4 | 198 | 7.5 | 1.0 |

| Stage 5 | 98 | 5 | 0.5 |

| Total 36.5 HP | |||

Traditional

5-Stage Continuous Washer

| Stage | Flow Rate | Pump HP | Rotator HP |

|---|---|---|---|

| Stage 1 | 1240 | 25 | N/A |

| Stage 2 | 450 | 15 | N/A |

| Stage 3 | 450 | 15 | N/A |

| Stage 4 | 840 | 20 | N/A |

| Stage 5 | 450 | 15 | N/A |

| Total 90 HP | |||

The HP required to operate the Torrent Washer™ is less than half that of the conventional washer which results in significant savings in both electrical usage and demand charges.

Monorail Washer Performance

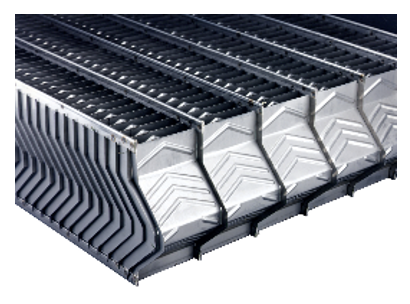

The rotating nozzle bars/arms create a swirling spray pattern which excels at cleaning the leading and trailing ends of the parts, as well as hard to reach pockets.

- Walls, roof, and drain boards are stainless steel

- Piping is stainless steel

- Wetted pumps are stainless steel

- Nozzles are stainless steel

- Stainless steel, welded, leak tested tanks

- Stainless steel tank covers with handles and latches

- VFD controlled vertical pumps

- The rotating risers have adjustable speed drive mechanisms, and thus are not dependent on water pressure

- The rotating unions are ceramic coated stainless steel, and oversized gearboxes are used for years of trouble-free service

- Header pressure is continuously monitored

- Stainless steel immersion heaters or plate-type heat exchangers

- Temperature is maintained via digital thermostats with feedback control

- Efficient insulation reduces heat loss and conserves energy

- PLC-based control panels with touchscreen HMIs

- Real-time monitoring of temperature, pressure, and chemical concentration

- Automatic alarms and shutdown features for safety and maintenance

- Data logging and system diagnostics

- Access doors

- Plank grating for internal walkways are stainless steel

- Screens in each tank located in the charge box areas, prior to the pumps

- Optional electronic liquid level sensing an control

- Optional internal lights

Industrial Monorail Washer Construction and Features

Stainless Steel Construction

Advanced Pump and Spray Systems

Heating Systems

Process Control Systems

Process Control Systems

Continuous Monorail Washer Accessories

Filter System for Monorail Parts Washers – High-performance stainless steel bag filter housings designed to integrate seamlessly with monorail parts washers. Each unit features isolation valves for safe and efficient servicing without interrupting washer operation. Solids are captured within the internal bag or basket, protecting spray nozzles and pumps from clogging and wear. Integrated pressure monitoring enables proactive maintenance, ensuring consistent filtration and extended equipment life in high-throughput monorail washing systems.

Magnetic Filter for Monorail Parts Washers - Designed to enhance the performance and longevity of monorail parts washers, this magnetic filter system captures ferrous particles from the return water stream before recirculation. As used wash water flows over the integrated drain board, it passes across a high-strength magnetic surface that efficienctly collects and retains fine magnetic debris such as machining fines or wear particles. This reduces system contamination, minimizes nozzle blockage, and improves overall wash quality in continuous, high-volume monorail operations.

Internal LED Lighting for Monorail Parts Washers - Enhance visibility and inspection capability inside your monorail parts washer with internal LED lighting, controlled directly from the operator interface terminal. The high-efficiency LED lights are mounted externally to avoid exposure to harsh wash environments and shine through a durable tempered glass window, providing clear illumination of the wash chamber without compromising system integrity. Ideal for maintennance checks, part monitoring, and ensuring consistent wash performance in continuous flow monorail systems.

Oil Coalescer for Monorail Parts Washers - Designed to improve fluid quality and reduce maintenance in monorail parts washer systems, the oil coalescer effectively removes floating oils and grease that accumulate during continuous washing operations. Wash solutions are first filtered, then passed through the coalescing unit where oil and grease are separated before the clean solution is returned to the main tank. Recovered contaminants are automatically rounted to a dedicated disposal container, helping to extend solution life, reduce maintenance downtime, and prevent issues in downstream waste treatment systems.

Blow-Off System for Monorail Parts Washers Positioned at the exit of the monorail parts washer, this high-efficiency blow-off system is engineered to remove excess moisture from parts before they continue down the production line. Equipped with a high-pressure blower and a VFD-controlled motor, the system provides adjustable airflow to accommodate varying part sizes and throughput rates. This helps reduce drying time, prevent water spotting or contamination, and prepare parts for downstream processes such as painting, assembly, or packaging.

Mist Eliminator for Monorail Parts Washers – The mist eliminator is designed to reduce airborne moisture and chemical carryover from the exhaust of monorail parts washers. Constructed with a durable stainless-steel framework, it effectively captures and separates fine liquid droplets from the vertical exhaust stream, preventing them from escaping into the facility environment. This improves air quality, protects downstream ventilation equipment, and supports compliance with air quality and safety standards in high-throughput monorail washing operations.

Water Treatment System for Monorail Parts Washers – Optimize performance and efficiency in your monorail parts washer with a complete water treatment system, including Reverse Osmosis (RO) technology. These systems help reduce overall water consumption, minimize chemical usage, and improve the consistency and quality of part finishes—especially critical in applications requiring a clean, residue-free surface. By supplying high-purity water to the washer, RO treatment helps extend solution life, reduce maintenance, and enhance downstream process reliability in high-volume monorail operations.

Brands